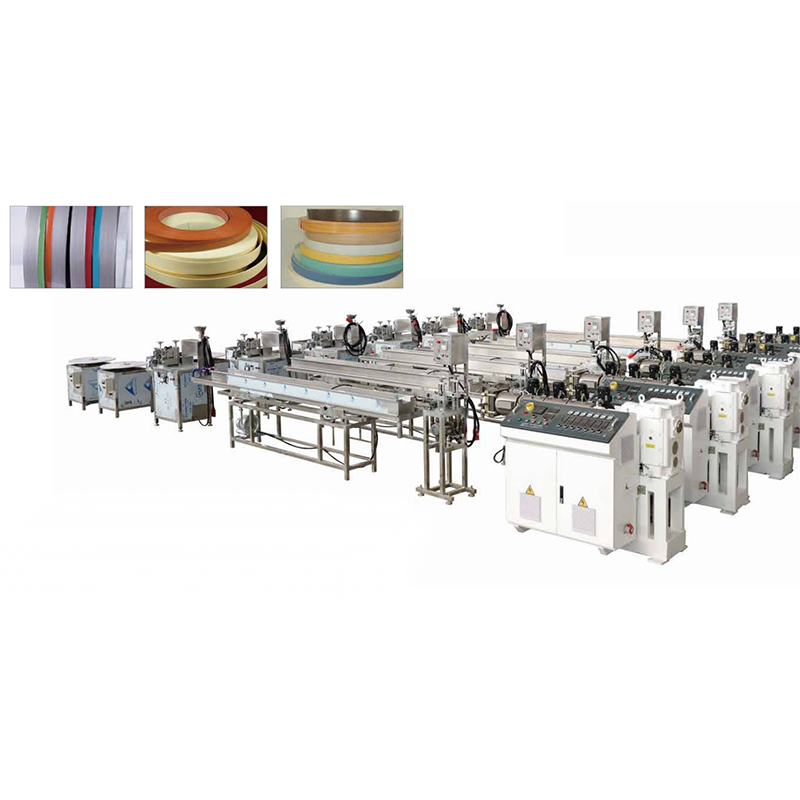

PVC Ntug Banding Extrusion Kab

Khoom nthuav qhia

Peb lub tuam txhab tau nqus cov thev naus laus zis siab tshaj plaws hauv tsev thiab txawv teb chaws thiab ua tiav kev tsim cov ntug banding ntau lawm kab tsim nyog rau cov kev xav tau ntawm cov neeg siv khoom. Cov kab ntau lawm muaj ib qho ntsia hlau extruder los yog ntxaib ntsia hlau extruder thiab pwm, embossing ntaus ntawv, lub tshuab nqus tsev, lub hau-tawm chav tsev raws li gluing rau cov menyuam ntaus ntawv, cua tshuab tshuab, txiav ntaus ntawv, lub tshuab winder thiab lwm yam ...

Main yam ntxwv:

Cov khoom lag luam muaj cov yam ntxwv zoo li plasticization zoo, muaj ntau hom xim, tswj kom raug, muaj peev xwm siab thiab siv zog tsawg. Nws tuaj yeem hloov PVC calendering ntawv tshuab. Lub extruder txais yuav txawv teb zaus inverter rau kev ceev ceev, tswj qhov kub thiab txias adopts Japanese Omron khoom. Lub tshuab auxiliary nrog lub tshuab nqus tsev twj tso kua mis thiab tshem tawm lub cev muaj zog txais cov khoom zoo rau kev saib xyuas yooj yim.

Daim ntawv thov tseem ceeb: rooj tog, wainscot ntawm cov khoom siv hauv chaw ua haujlwm, ntug banding, ntim thermoforming thiab lwm yam.

Technical parameter

| Qauv | Tsav lub cev muaj zog | Ntsia hlau rpm | Muaj peev xwm | Cov khoom | Thickness |

| JWS 45/25 | 11 kWm | 5-50 rpm | 15-20Kg / h | 12-35 hli | 0.4-1 hli |

| JWS 50/25 | 15 KW | 5-50 rpm | 25-30Kg / h | 12-35 hli | 0.4-1 hli |

| JWS 55/25 | 18.5 KW TSI | 5-50 rpm | 30-50Kg / h | 12-45 hli | 0.4-2 hli |

| JWS 65/25 | 22 kwv | 5-50 rpm | 50-60Kg / h | 12-45 hli | 0.4-2 hli |