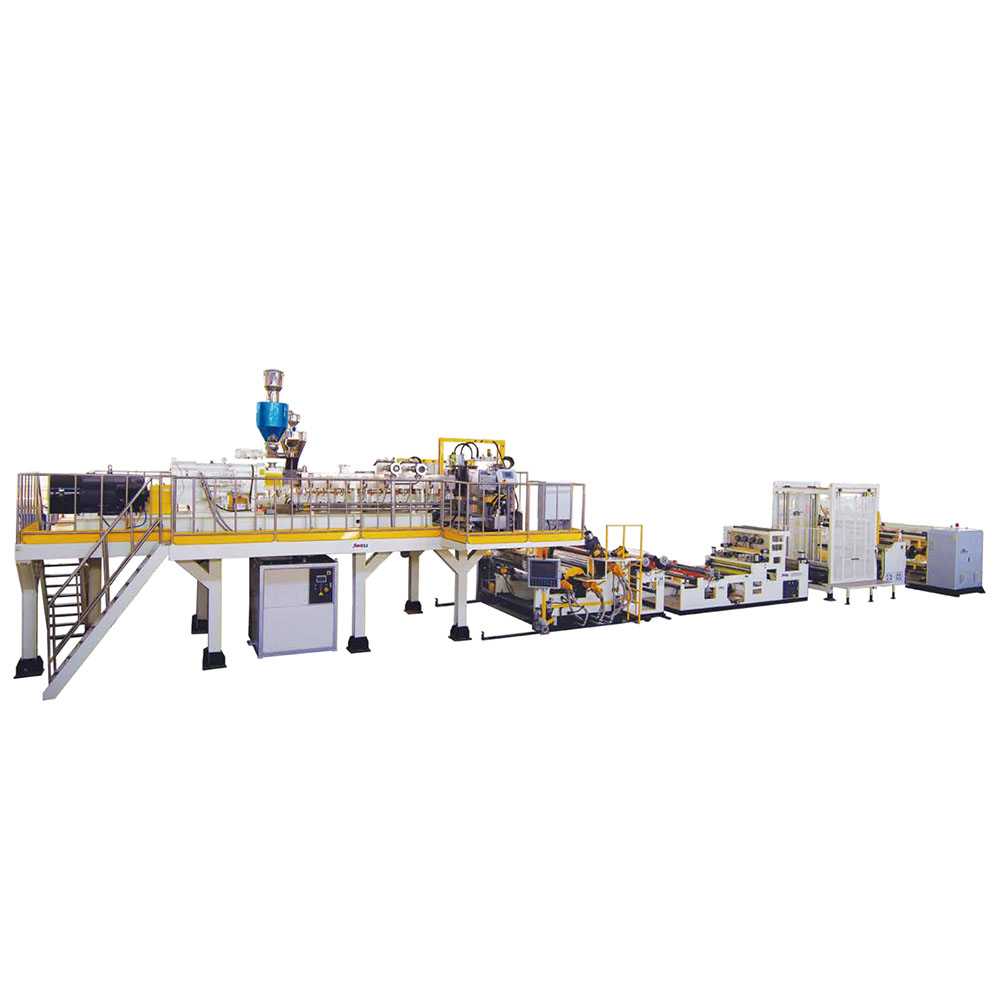

PET / PLA Ntawv Extrusion Kab

Main Technical Parameter

| Qauv | Extruder qauv | Khoom thickness (mm) | Main lub cev muaj zog (kw) | Max extrusion peev (kg / h) |

| Ntau txheej | JWE75/40+JWE52/40-1000 | 0.15-1.5 hli | 132/15 ib | 500-600 |

| Ib txheej | JWE75/40-1000 | 0.15-1.5 hli | 160 | 450-550 |

| Ua tau zoo heev | JWE95/44+JWE65/44-1500 | 0.15-1.5 hli | 250/75 ib | 1000-1200 Nws |

| Ua tau zoo heev | JWE110+JWE65-1500 | 0.15-1.5 hli | 355/75 ib | 1000-1500 |

Nco tseg: Cov kev qhia tshwj xeeb yuav hloov pauv yam tsis tau ceeb toom ua ntej.

Main Technical Parameter

| Qauv | Ntau txheej | Ib txheej | Ua tau zoo heev |

| Extruder specification | JW120/65-1000 | JW120-1000 | JW150-1500 |

| Thickness ntawm cov khoom | 0.20-1.5 hli | 0.2-1.5 hli | 0.2-1.5 hli |

| Main lub cev muaj zog | 132kw/45kw | 132 kwv | 200 kwv |

| Max extrusion muaj peev xwm | 600-700kg / h | 550-650kg / h | 800-1000kg / h |

Nco tseg: Cov kev qhia tshwj xeeb yuav hloov pauv yam tsis tau ceeb toom ua ntej.

PLA daim ntawv

PLA yog hom kab zoo li Aliphatic Polyesters. PLA tuaj yeem siv rau hauv pob txha ntawm cov txiv hmab txiv ntoo, zaub, qe, cov zaub mov siav thiab cov zaub mov ci, kuj tuaj yeem siv rau ntim cov qhaub cij, biscuit thiab lwm yam pob khoom xws li paj tshiab.

Product Description

Polylactic acid (PLA) tuaj yeem decomposed tag nrho rau hauv carbon dioxide thiab dej nyob rau hauv tej yam ntuj tso tej yam kev mob tom qab muab pov tseg. Nws muaj cov dej tsis zoo, cov khoom siv kho tshuab, biocompatibility, tuaj yeem nqus tau los ntawm cov kab mob, thiab tsis muaj kuab paug rau ib puag ncig. Tib lub sijhawm, PLA kuj muaj cov khoom siv kho tshuab zoo. Nws muaj kev cuam tshuam lub zog, zoo saj zawg zog thiab thermal stability, plasticity, processability, tsis muaj discoloration, zoo permeability rau oxygen thiab dej vapor, thiab zoo transparency, anti-mildew, antibacterial, lub neej kev pab cuam yog 2 ~ 3 xyoo.

Qhov tseem ceeb tshaj plaws Performance index ntawm ntim cov ntaub ntawv yog huab cua permeability, thiab daim ntawv thov teb ntawm cov khoom no nyob rau hauv ntim yuav txiav txim raws li qhov sib txawv huab cua permeability ntawm cov ntaub ntawv. Qee cov ntaub ntawv ntim khoom xav tau cov pa oxygen permeability kom txaus oxygen rau cov khoom; qee cov ntaub ntawv ntim khoom yuav tsum muaj kev cuam tshuam rau cov pa oxygen ntawm cov ntaub ntawv, xws li cov ntim dej haus, uas yuav tsum muaj cov ntaub ntawv uas tuaj yeem tiv thaiv cov pa oxygen nkag mus rau hauv lub pob kom inhibit pwm. cov nyhuv ntawm kev loj hlob. PLA muaj roj barrier, dej barrier, pob tshab thiab zoo printability.

PLA muaj cov pob tshab zoo thiab gloss, thiab nws cov kev ua tau zoo yog piv rau cellophane thiab PET, uas tsis muaj nyob rau hauv lwm cov yas degradable. Lub pob tshab thiab ci ntawm PLA yog 2 ~ 3 npaug ntawm cov yeeb yaj kiab PP thiab 10 npaug ntawm LDPE. Nws cov pob tshab siab ua rau pom kev siv PLA ua cov khoom ntim zoo nkauj. Piv txwv li, nws yog siv rau kev ntim khoom qab zib. Tam sim no, ntau lub hnab ntim khoom qab zib hauv khw siv PLA ntim zaj duab xis.

Cov tsos thiab kev ua tau zoo ntawm cov ntim zaj duab xis no zoo ib yam li cov khoom qab zib ntim cov yeeb yaj kiab, nrog cov pob tshab siab, zoo heev kink tuav, luam tawm thiab lub zog, nrog rau cov khoom thaiv zoo heev, uas tuaj yeem khaws cov khoom qab zib zoo dua. Ib lub tuam txhab Nyij Pooj siv "racea" hom PLA ntawm American Cakir Dow Polymer Company ua cov khoom ntim rau cov khoom tshiab, thiab lub ntim yog pob tshab heev. Toray Industries tau tsim PLA cov yeeb yaj kiab ua haujlwm thiab cov hlais siv nws cov cuab yeej nano-alloy technology. Cov yeeb yaj kiab no muaj tib lub tshav kub thiab kev cuam tshuam tsis zoo xws li roj av-raws li cov yeeb yaj kiab, tab sis kuj muaj cov elasticity zoo heev thiab pob tshab.

PLA tuaj yeem ua rau hauv cov khoom ua yeeb yaj kiab nrog cov pob tshab, cov khoom thaiv zoo, kev ua haujlwm zoo thiab cov khoom siv kho tshuab, thiab tuaj yeem siv rau kev ntim cov txiv hmab txiv ntoo thiab zaub. Nws tuaj yeem tsim qhov chaw cia khoom tsim nyog rau cov txiv hmab txiv ntoo thiab zaub, tswj lub neej ua haujlwm ntawm cov txiv hmab txiv ntoo thiab zaub, ncua kev laus, thiab tswj cov xim, aroma, saj thiab tsos ntawm txiv hmab txiv ntoo thiab zaub. Txawm li cas los xij, thaum siv rau cov khoom ntim khoom noj tiag tiag, qee qhov kev hloov kho yuav tsum tau hloov mus rau cov yam ntxwv ntawm cov zaub mov nws tus kheej, thiaj li ua tiav cov txiaj ntsig zoo dua.

PLA tuaj yeem tsim ib qho chaw tsis muaj zog acidic ntawm qhov chaw ntawm cov khoom, uas muaj lub hauv paus ntawm cov kab mob thiab cov tshuaj tua kab mob. Yog tias siv lwm cov tshuaj tua kab mob ntxiv, cov tshuaj tua kab mob ntau dua 90% tuaj yeem ua tiav, uas tuaj yeem siv rau kev ntim tshuaj tua kab mob ntawm cov khoom.

Piv nrog LDPE zaj duab xis, PLA zaj duab xis thiab PLA / REO / TiO2 zaj duab xis, cov dej permeability ntawm PLA / REO / Ag composite zaj duab xis yog ntau dua li ntawm lwm cov yeeb yaj kiab. Nws tau xaus lus los ntawm qhov no tias nws tuaj yeem tiv thaiv kev tsim cov dej condensed thiab ua tiav cov txiaj ntsig ntawm inhibiting kev loj hlob ntawm cov kab mob; Nyob rau tib lub sijhawm, nws kuj muaj cov nyhuv bacteriostatic zoo heev.

PET / PLA ib puag ncig daim ntawv extrusion kab: JWELL tsim cov kab sib txuas ntxaib ntsia hlau extrusion kab rau PET / PLA daim ntawv, cov kab no nruab nrog degassing system, thiab tsis tas yuav ziab thiab crystallizing chav tsev. Cov kab extrusion muaj cov khoom ntawm cov khoom siv hluav taws xob tsawg, cov txheej txheem tsim khoom yooj yim thiab kev saib xyuas yooj yim. Lub segmented ntsia hlau qauv tuaj yeem txo qhov viscosity poob ntawm PET / PLA resin, symmetrical thiab nyias-phab ntsa calender rau cov menyuam ua kom txias txias thiab txhim kho lub peev xwm thiab cov ntawv zoo. Ntau yam khoom noj pub noj tuaj yeem tswj tau qhov feem pua ntawm cov khoom siv nkauj xwb, cov khoom siv rov ua dua tshiab thiab cov khoom lag luam zoo meej, daim ntawv yog dav siv rau kev lag luam ntim thermoforming.